What are the key features to look for in a spot welding machine?

When choosing a spot welding machine, look for features such as adjustable welding current, efficient cooling systems, and ease of use with clear controls. Ensure the machine has a robust build for durability and a power range suitable for your specific welding needs, whether for automotive, sheet metal, or DIY projects. Compact models like mini spot welders are ideal for smaller tasks and spaces.

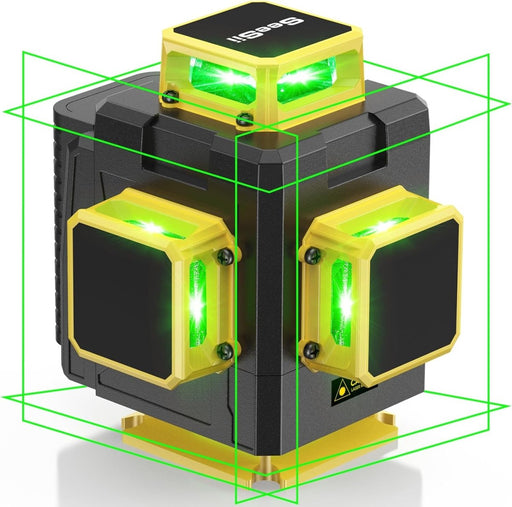

How does a laser level improve accuracy in electrical work and construction projects?

A laser level is essential for electricians and construction professionals as it projects highly visible, straight lines onto surfaces, ensuring precise alignment for installations like wiring, outlets, and fixtures. This tool significantly reduces measurement errors, saves time, and increases the overall accuracy of the project by maintaining even, level surfaces.

What are the must-have impact tools for professional electricians?

Professional electricians should have a selection of impact tools, such as impact drivers and impact wrenches, to handle various tasks that require fastening and loosening screws, bolts, and nuts efficiently. These tools provide powerful torque, making them ideal for tasks involving tougher materials or when speed and efficiency are needed for electrical installations and repairs.

What are the benefits of using a mini spot welder for small welding projects?

Mini spot welders are perfect for small welding projects due to their compact size and portability, making them easy to maneuver in tight spaces. They are energy-efficient, often provide precise welds, and are suitable for thin materials such as small metal sheets and battery tabs. Their simplicity makes them user-friendly for hobbyists and professionals needing a lightweight yet effective welding solution.

Which equipment for welding should be included in a beginner's starter kit?

A beginner’s welding kit should include a reliable spot welding machine or mini spot welder, protective gear (welding mask, gloves, and apron), welding rods or wire, and a chipping hammer. Depending on the projects, additional items like clamps and a welding table may be beneficial. For more versatile tasks, an arc or MIG welder could be considered as part of the starter kit.

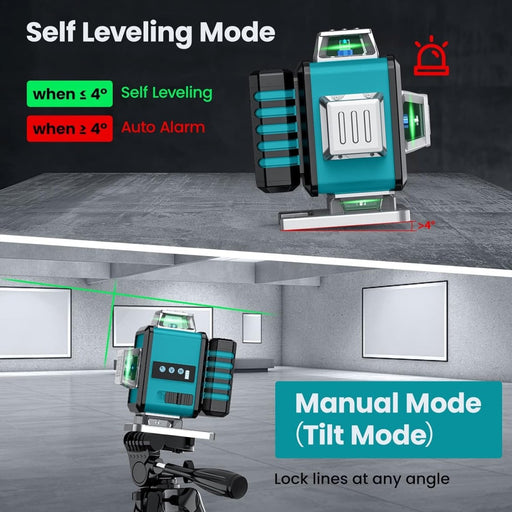

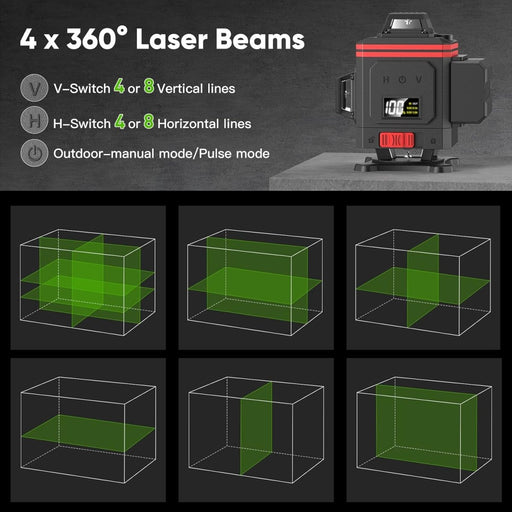

What are the different types of laser levels and how are they used in construction and electrical work?

Laser levels come in various types, including line lasers, rotary lasers, and dot lasers. Line lasers project straight horizontal or vertical lines and are commonly used for leveling and aligning electrical outlets or fixtures. Rotary lasers provide 360-degree coverage, making them ideal for large spaces, while dot lasers project points that help in precise placement tasks. Electricians and construction workers use these tools to ensure straight, level installations.

What safety tips should I follow when using impact tools in electrical work?

When using impact tools in electrical work, always wear safety goggles and gloves to protect your eyes and hands from debris and accidental slips. Ensure the tool is properly rated for the task and check that it is in good condition before use. Secure the workpiece firmly, maintain a stable grip, and be mindful of nearby cables or components to prevent accidental damage or injury.

How do spot welding machines differ from traditional welding equipment?

Spot welding machines focus on joining two metal pieces at specific points using heat generated from an electrical current, making them ideal for sheet metal work and tasks where quick, precise welds are required. Traditional welding equipment, like MIG or TIG welders, allows for continuous or seam welding and can be used for a wider range of metal thicknesses. Spot welding machines are often simpler to operate and more cost-effective for repetitive tasks.